Guide for Developing Job Safety Analyses & Safe Work Procedures

What is a Job Safety Analysis or Safe Work Procedure?

Job Safety Analyses (JSA) and Safety Work Procedures (SWP) (also known as job hazard analysis/analyses, pre job plan, safe work plan, etc.) are step by step instructions for doing work the right way. JSAs and SWPs identify the materials and equipment needed, how and when to use them, and usually include:

- regulatory requirements;

- personal protective equipment requirements;

- training requirements;

- responsibilities of each person involved in the job;

- a specific sequence of steps to follow to complete the work safely; permits required;

- emergency procedures.

Why Use a JSA or SWP?

JSAs and SWPs are generally prepared for jobs that:

- are critical (high risk jobs where accidents have or could result in severe injuries);

- are hazardous and where accidents occur frequently;

- new or have been changed;

- have had new equipment added;

- require many detailed tasks;

- involve two or more workers who must perform specific tasks simultaneously;

- are done infrequently.

10 Steps to Create a Job Safety Analysis (JSA) or Safe Work Procedure (SWP)

- An easy way to develop a job safety analysis or safe work procedure procedure is to break the task into small steps. For each step, determine the hazards and ways to correct them. Some hazards to think about include: being struck by moving equipment; coming in contact with hazardous substances; hitting obstructions or other workers; becoming caught in machinery; falling; being struck by objects falling from above; suffering from exposure to toxic gases, insufficient oxygen or extreme temperatures.

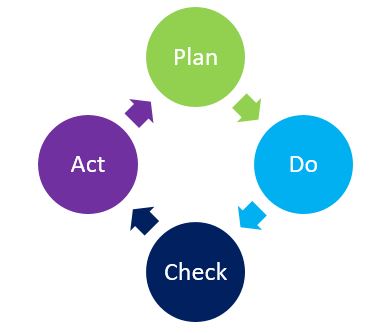

- You can then use the breakdown of hazards and corrective measures to prepare a written JSA or SWP. Consider using the following process to develop your safe work procedures. List all jobs on your work sites that meet the criteria above. Concentrate on those that have potential for: serious injuries; frequent injures; severe property damage; significant interruptions to production; public liability; government intervention.

- Put the list of jobs in order by the degree of hazard they present and the frequency they are performed.

- Analyze each job by observing and interviewing workers. Record the following information: job name and location; each step of the job and its hazards; roles of each worker involved; special equipment required; applicable regulatory requirements.

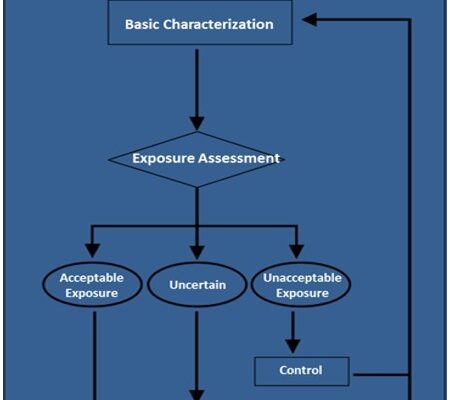

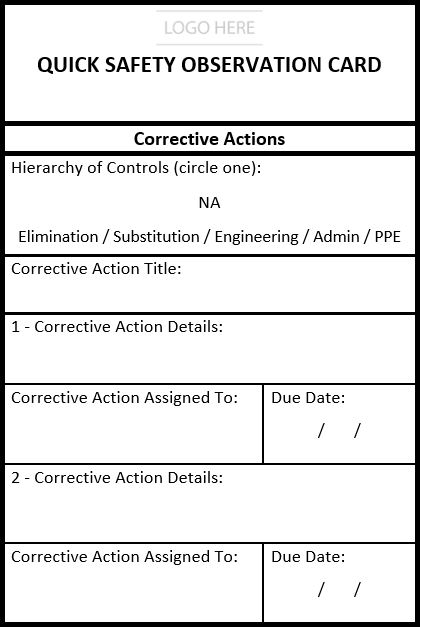

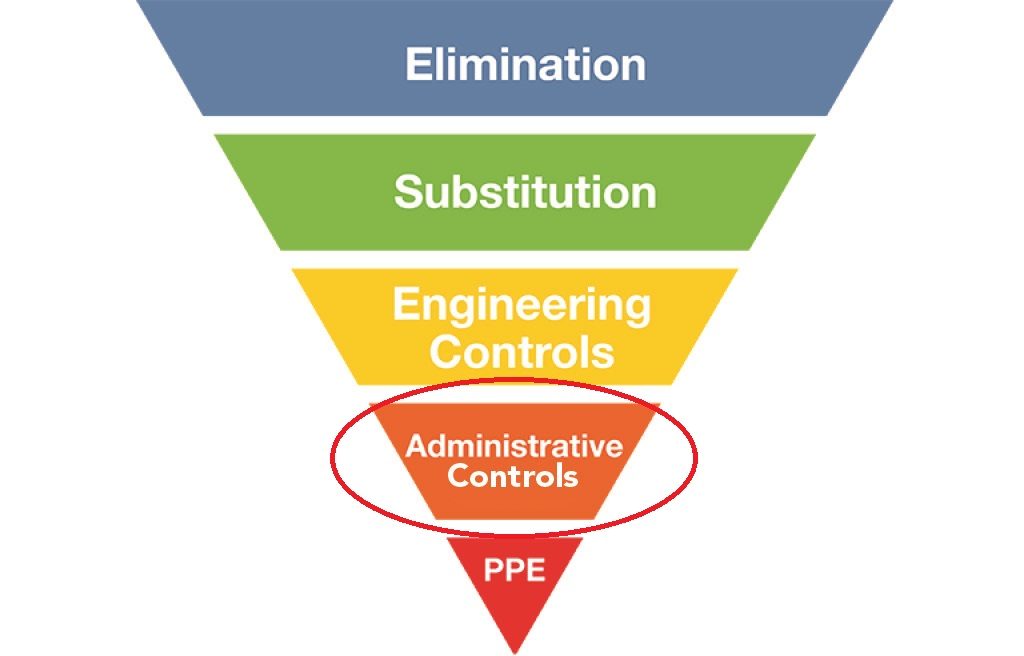

- Determine the measures needed to control job hazards, such as: engineering controls to eliminate hazards; worker training; personal protective and safety equipment; hazard markings; safety meetings.

- If engineering controls or worker training can be used to permanently eliminate or reduce the impact of hazards, implement them.

- Prepare your safe work procedure by listing (in order of occurrence) each: step of the job; control measure required (excluding one time measures such as engineering controls and development of training); regulatory requirement; special equipment required; specific training requirement for workers (e.g., BOP Level l or journeyman electrician).

- Test the procedure in the field to ensure it: is accurate; meets regulatory requirements; is understandable to workers.

- Finalize the written procedure and place it at appropriate work sites.

- Train workers in the procedures.