Workers Memorial Day – April 28, 2009

Workers Memorial Day is April 28. Established to remember those who have been injured or killed in the workplace.

Workers Memorial Day is April 28. Established to remember those who have been injured or killed in the workplace.

According to NIOSH and the CDC:

- 16 workers die each day from injuries sustained at work

- 134 workers die each day from work-related diseases

- In 2007, 5,488 U.S. workers died form work-related injuries

- In 2007, 4 million people in the private sector had a non-fatal work-related injury/illness

- In 2004, approximately 3.4 million workers were treated in emergency rooms due to occupational injuries

- In 2005, worker’s compensation cost employers approximately $89 billion USD

The Acting Director of NIOSH offered the following statement:

Workers Memorial Day serves a somber but necessary purpose: “Never forget.” Remember and honor those who have died on the job. Do not let their memories fade. Find inspiration to redouble our efforts to keep the living both safe and healthy at work.

On Workers Memorial Day 2009, as the nation strives to recover from the present economic crisis, it is also important to note that the human benefits of occupational safety and health are intertwined with benefits for our economy and our social fabric. Proven strategies to help keep working men and women whole and healthy are integral to economic recovery and our national reinvestment in America’s future, as these examples suggest:

* Operating a safe and healthy workplace helps businesses to stay profitable and competitive – a must in today’s economic climate.

* Preventing the death, disability, or impairment of a mother or father averts a loss that can disrupt a working family’s economic security and emotional stability.

* As new technologies and industries emerge with promise for fueling present recovery and future prosperity, good stewardship in safety and health will be key for avoiding potential unintended consequences, and for fostering wise investment and growth.

* Preventing injuries and illnesses that result in costly medical treatment and insurance bills, supporting a robust health-care workforce for today, and helping to train tomorrow’s skilled providers – all are vital needs in health-care reform. All involve substantial occupational safety and health components.It is as true today as it was in 1971, when the National Institute for Occupational Safety and Health (NIOSH) opened its doors, that scientific research is crucial for meeting the nation’s safety and health needs. In the 38 years since then, and in the 20 years since the first Workers Memorial Day, our efforts have helped to drive great advancements in worker protection. However, as we are reminded by Workers Memorial Day 2009, much more remains to be done.

NIOSH is proud to strive with our diverse partners to meet this challenge. We remember the victims of workplace death with sorrow, and we look forward to a better future in which no one dies from job-related causes.

A pandemic is a global disease outbreak. An influenza pandemic occurs when a new influenza virus emerges for which there is little or no immunity in the human population; begins to cause serious illness; and then spreads easily person-to-person worldwide. A worldwide influenza pandemic could have a major effect on the global economy, including travel, trade, tourism, food, consumption and eventually, investment and financial markets. Planning for pandemic influenza by business and industry is essential to minimize a pandemic’s impact.

A pandemic is a global disease outbreak. An influenza pandemic occurs when a new influenza virus emerges for which there is little or no immunity in the human population; begins to cause serious illness; and then spreads easily person-to-person worldwide. A worldwide influenza pandemic could have a major effect on the global economy, including travel, trade, tourism, food, consumption and eventually, investment and financial markets. Planning for pandemic influenza by business and industry is essential to minimize a pandemic’s impact.

The mortality benefits of restricting the use of asbestos should begin to appear after 2010, when deaths from malignant mesothelioma are expected to peak, according to a report from the CDC.

The mortality benefits of restricting the use of asbestos should begin to appear after 2010, when deaths from malignant mesothelioma are expected to peak, according to a report from the CDC. The

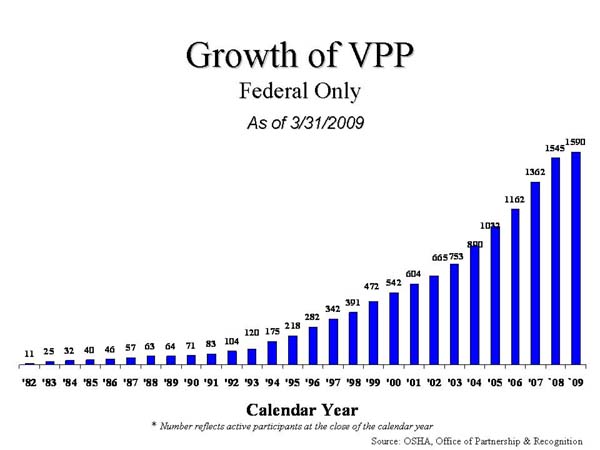

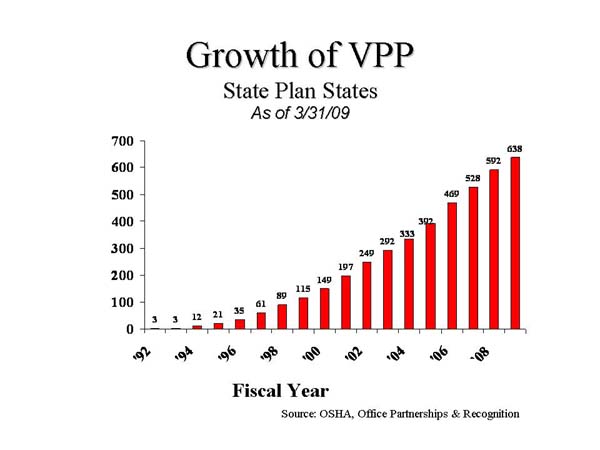

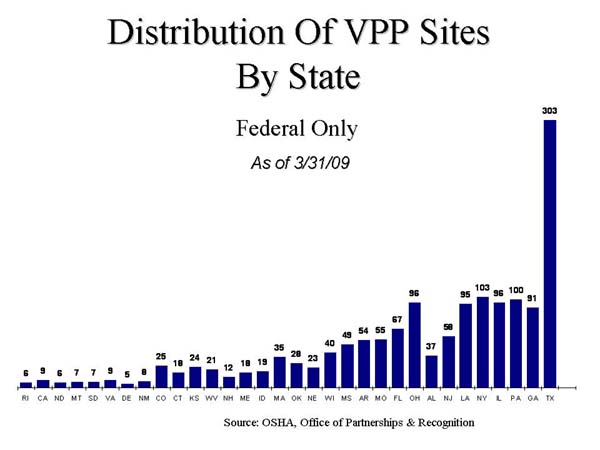

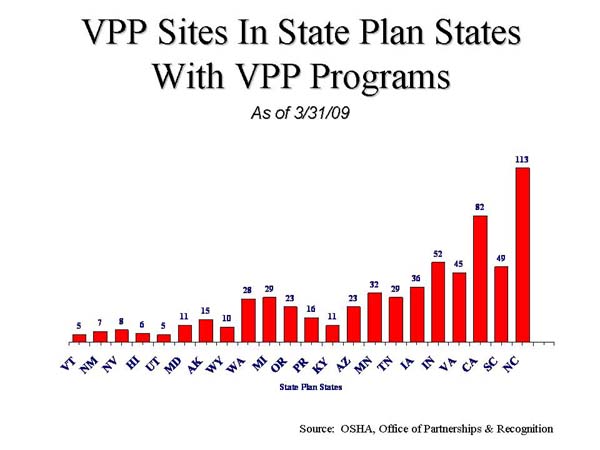

The  “The Voluntary Protection Programs (VPP) promote effective worksite-based safety and health. In the VPP, management, labor, and OSHA establish cooperative relationships at workplaces that have implemented a comprehensive safety and health management system. Approval into VPP is OSHA’s official recognition of the outstanding efforts of employers and employees who have achieved exemplary occupational safety and health.”

“The Voluntary Protection Programs (VPP) promote effective worksite-based safety and health. In the VPP, management, labor, and OSHA establish cooperative relationships at workplaces that have implemented a comprehensive safety and health management system. Approval into VPP is OSHA’s official recognition of the outstanding efforts of employers and employees who have achieved exemplary occupational safety and health.”

The purpose of this memorandum is to resolve issues concerning adjustments of the PEL during extended work shifts. This applies for exposures to the noise levels of Table G-16 of 29 CFR 1910.95 or substances found in Subpart Z. Current OSHA policy requires only the action level to be reduced for exposures to noise during extended work shifts; the PEL is not required to be adjusted. The only standards which require PEL adjustments are the lead standards in construction and general industry. These standards have a specific provision which requires work shift adjustments. Existing policy for Occupational Exposure to Cotton Dust also has a requirement to adjust extended work shifts when employees are required to wear respirators for a portion of the work shift to reduce their level of exposure, as set forth in the Federal Register, Vol. 45, No. 251, pp. 85736-85739. The contribution that the extended work hours adds to employee exposure must be included in calculating the required time respirators must be worn during the shift.

The purpose of this memorandum is to resolve issues concerning adjustments of the PEL during extended work shifts. This applies for exposures to the noise levels of Table G-16 of 29 CFR 1910.95 or substances found in Subpart Z. Current OSHA policy requires only the action level to be reduced for exposures to noise during extended work shifts; the PEL is not required to be adjusted. The only standards which require PEL adjustments are the lead standards in construction and general industry. These standards have a specific provision which requires work shift adjustments. Existing policy for Occupational Exposure to Cotton Dust also has a requirement to adjust extended work shifts when employees are required to wear respirators for a portion of the work shift to reduce their level of exposure, as set forth in the Federal Register, Vol. 45, No. 251, pp. 85736-85739. The contribution that the extended work hours adds to employee exposure must be included in calculating the required time respirators must be worn during the shift. “Speaking on April 19 at the Experimental Biology 2009 meeting in New Orleans, Dr. Kristine Krajnak, a team leader in the Engineering and Control Technologies Branch of the Health Effects Laboratory Division of NIOSH in Morgantown, West Virginia, describes results from the first study to directly link the different physical responses of tissue that occur with exposure to different vibration frequencies with biological mechanisms underlying the development of vascular dysfunction. Her presentation is part of the scientific program of The American Physiological Society.

“Speaking on April 19 at the Experimental Biology 2009 meeting in New Orleans, Dr. Kristine Krajnak, a team leader in the Engineering and Control Technologies Branch of the Health Effects Laboratory Division of NIOSH in Morgantown, West Virginia, describes results from the first study to directly link the different physical responses of tissue that occur with exposure to different vibration frequencies with biological mechanisms underlying the development of vascular dysfunction. Her presentation is part of the scientific program of The American Physiological Society. OSHA notified over 13,500 employers in April 2009 regarding their higher than average injury and illness rates. OSHA stated that the letter was an attempt to make the employers aware of their rates and to encourage them to work to lower the rates and improve their overall health and safety via:

OSHA notified over 13,500 employers in April 2009 regarding their higher than average injury and illness rates. OSHA stated that the letter was an attempt to make the employers aware of their rates and to encourage them to work to lower the rates and improve their overall health and safety via: There are some 82,000 chemicals used commercially in the U.S., but only a fraction have been tested to make sure they’re safe and just five are regulated by the U.S. Environmental Protection Agency (EPA), according to congressional investigators. But a government scientist says there’s no guarantee testing actually rules out health risks anyway.

There are some 82,000 chemicals used commercially in the U.S., but only a fraction have been tested to make sure they’re safe and just five are regulated by the U.S. Environmental Protection Agency (EPA), according to congressional investigators. But a government scientist says there’s no guarantee testing actually rules out health risks anyway. AIHA offered the following recommendations: 1) “for the periodic inspection and maintenance of engineering controls and equipment, recordkeeping of the results of the inspections, and correction of any problems found during the inspections within a reasonable time.” 2) “determine whether or not it is possible for OSHA to promulgate a final standard within 18 months of enactment of the legislation.”

AIHA offered the following recommendations: 1) “for the periodic inspection and maintenance of engineering controls and equipment, recordkeeping of the results of the inspections, and correction of any problems found during the inspections within a reasonable time.” 2) “determine whether or not it is possible for OSHA to promulgate a final standard within 18 months of enactment of the legislation.”