Free eTool: Industrial Hygiene Exposure Assessment Characterization

Anticipate, Identify, Recognize

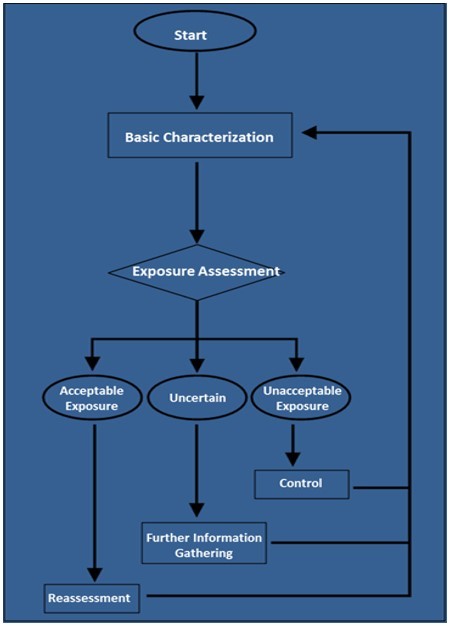

When starting an occupational exposure assessment, the first step a practicing industrial hygienist must do is be able to anticipate, identify, and/or recognize workplace hazards so that stressors that may impact employee health can be evaluated later in the assessment. Understanding the workplace, how chemical and physical agents are generated and the existing control measures (e.g. engineering controls) in place, help the industrial hygienist to develop an effective plan for evaluating risks.

IHEST – Industrial Hygiene Exposure Scenario Tool

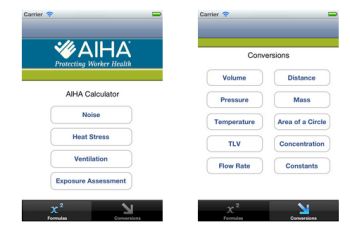

AIHA has released the free IHEST (Industrial Hygiene Exposure Scenario Tool) which helps an industrial hygienist to identify and capture basic exposure potential data, for the purpose of improving evaluation accuracy in the assessment process. The tool includes prompts for:

- Process Overview

- Task Description

- Exposure Controls

- Similar Exposure Groups

- Employee Tasks

- Ventilation

- Room layout

- Airborne concentrations

- Dermal exposures, and

- Noise exposures

Download a copy of the AIHA IHEST from AIHA’s website or without macros below.

Source: AIHA

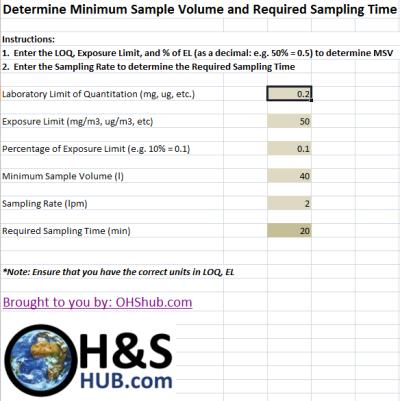

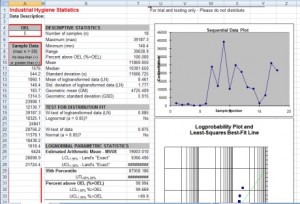

Statistical Analysis of Health & Safety Data – IHSTAT

Are you looking for statistical analysis of health and safety data (e.g. number of measured occupational exposures that exceed established OELS)? Take a look at OHShub.com’s post on IHSTAT, where you can download AIHA’s excel worksheet that can perform some basic statistics for you.

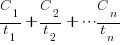

Below is a summary of some of the very similar methods and rationale used by agencies to assess the combined toxic effects of chemicals.

Below is a summary of some of the very similar methods and rationale used by agencies to assess the combined toxic effects of chemicals.

The purpose of this memorandum is to resolve issues concerning adjustments of the PEL during extended work shifts. This applies for exposures to the noise levels of Table G-16 of 29 CFR 1910.95 or substances found in Subpart Z. Current OSHA policy requires only the action level to be reduced for exposures to noise during extended work shifts; the PEL is not required to be adjusted. The only standards which require PEL adjustments are the lead standards in construction and general industry. These standards have a specific provision which requires work shift adjustments. Existing policy for Occupational Exposure to Cotton Dust also has a requirement to adjust extended work shifts when employees are required to wear respirators for a portion of the work shift to reduce their level of exposure, as set forth in the Federal Register, Vol. 45, No. 251, pp. 85736-85739. The contribution that the extended work hours adds to employee exposure must be included in calculating the required time respirators must be worn during the shift.

The purpose of this memorandum is to resolve issues concerning adjustments of the PEL during extended work shifts. This applies for exposures to the noise levels of Table G-16 of 29 CFR 1910.95 or substances found in Subpart Z. Current OSHA policy requires only the action level to be reduced for exposures to noise during extended work shifts; the PEL is not required to be adjusted. The only standards which require PEL adjustments are the lead standards in construction and general industry. These standards have a specific provision which requires work shift adjustments. Existing policy for Occupational Exposure to Cotton Dust also has a requirement to adjust extended work shifts when employees are required to wear respirators for a portion of the work shift to reduce their level of exposure, as set forth in the Federal Register, Vol. 45, No. 251, pp. 85736-85739. The contribution that the extended work hours adds to employee exposure must be included in calculating the required time respirators must be worn during the shift.